Quality Movement

We - The motivated and devoted work-force of AMUL- are committed to produce wholesome and safe foods of excellent quality to remain market leader through deployment of quality management systems, state-of-art-technology, innovation and eco-friendly operations to achieve delightment of customers and betterment of milk producers.

Quality Management System Initiatives: The initiation of Total Quality Management (TQM) way back in 1994 was to work with the well known quality management initiatives which have proven to be effective elsewhere to create a culture of transparency, openness and leadership in the organization. Realizing that with emerging competition, doing business would become more exciting yet extremely competitive which would require at time not only a whole set of new skills and competencies but quick adaptability to change without much stress or turbulence. As a very unique measure Amul extended all the TQM initiatives to its business partners whether it was the farmer producer in the village or a wholesale distributor in a metro town or its most sophisticated production unit.

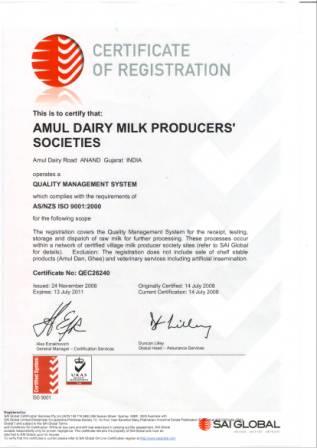

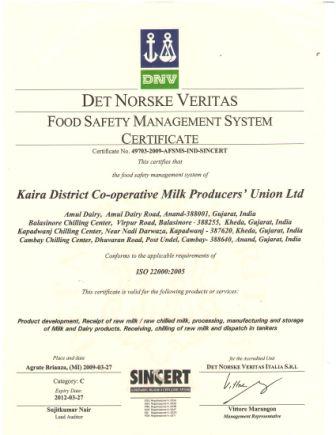

From the strength of Total Quality Management initiative Amul went on to implement Quality Management System of International Standard. Amul has been the first dairy in India to get accredited with certification of ISO 2200:2005 & ISO 9001 for its operations and plants. Further Amul has set an example that village Dairy Co-operative Societies could also achieve this milestone as these societies are accredited with ISO 9001:2000 – a remarkable achievement in the history of India.

Amul Plants are certified by Agricultural and Processed Food Exports Development Authority (APEDA) for export of dairy products to international markets. Gujarat Co-operative Milk Marketing Federation (GCMMF) which markets and exports dairy products under the brand of “Amul” has bagged award 11th time for excellent performance in exports of dairy products from APEDA - 2008-09, IMC Ramkrishna Bajaj National Quality Award – 2003, "Best Best of All" Rajiv Gandhi National Quality Award - 1999, The International Dairy Federation Marketing Award (2007) for Amul pro-biotic ice-cream launch.

Amul Dairy has been recipient of countless awards for its outstanding efforts in processing and providing quality products to consumers thereby enhanced income in to the hands of dairy farmers. Some of these awards are the Best Productivity Performance Awards for three consecutive years from 1985 and Sustained productivity Performance Award in 1988-89 from National Productivity Council, Government of India, Indian Merchants’ Chamber Award - for Outstanding Performance in the field of R&D of Food Processing Industries Based on Agricultural Products -1988, again Best Productivity Performance Awards 1994-99 from National productivity Council, G. D. Birla International Award - Outstanding Contribution to Rural Upliftment , Sahkari Vikas Ratna Award – awarded on the occasion of Indian Co-operative Centenary Celebration for the outstanding contributions in the field of Dairy Co-operative movement in Asia – 2005, National Energy Conservation Award – 2009 from Ministry of Power, Government of India.

FOOD SAFETY POLICY: We at AMUL, are committed to produce safe and wholesome food to continually remain as the market leader by providing food products delighting customer expectations and bestow safety. We strive to achieve this by, Improving raw milk quality, Applying innovative technology for manufacturing food products, Employing quality and food safety management practices to, manufacture food products in a eco-friendly environment, Meeting applicable statutory and regulatory requirements, Effectively communicate and constantly improve professional skills of employees emphasizing continuous improvement of quality and food safety issues.

Amul has implemented the Quality Management System of international standard to offer ‘invaluable’ products to national and international customers. Its plants are certified for ISO 22000:2005 for excellence in food safety management system.

ISO Accreditation of Primary Dairy Co-operative Societies: Amul’s primary village cooperative societies are the first ‘grass root level’ organizations in the rural sector to achieve ISO 9001 : 2000 certification in India, perhaps in the world. This has been possible because of Amul’s continued commitment to offer consumers excellent products from the house of Amul.

The focus on health and hygiene, housekeeping, village chilling units, management of village co-operative societies, rapid transportation of raw milk to dairy plant, accelerated milk handling at the dairy reception dock has retained the freshness of milk being received at dairy plant. To sustain and rebuild on this effort, training programmes are organised for all the stakeholder groups involved in the ‘milk procurement chain’, namely, milk producers, village society personnel and dairy plant personnel. Laboratories are equipped with state of the art equipments and well trained professionals.

Hygienic & Clean Milk Production Drive: The primary village dairy co-operative societies operate every morning and evening for the village farmers. Milk delivered by a producer is measured and a sample is drawn for a quality-testing. Each centre is equipped with an electronic milko-tester for testing quality of milk, automatic weighing machine for weighing of milk with data processing facilities. The entire operation is electronically captured with member-id. Various training programmes, especially on quality management system, good management practises in animal husbandry are imparted on continuous basis to member producers, dairy co-operative personnel and personnel at dairy plants.

Bulk Milk Chillers: (BMCs) As a part of Amul’s quality movement Bulk Milk Chillers are introduced at primary village co-operative society level. This system has drastically improved the microbiological quality of milk, therefore better return to farmers and good quality of products to consumers. Special trainings are imparted to dairy co-operative personnel for better management of Bulk Milk Chillers.

Road Milk Tankers: The chilled milk of the co-operative societies are transported to Amul Dairy Plant through road milk tankers once in a day. These milk tankers are insulated to safeguard the quality of milk. A tanker carries three to four societies’ milk together which helps in achieving economy in transportation of milk. These tankers are thoroughly cleaned at every unloading of milk at Dairy Plant and certified for its hygiene for transportation of milk by QC personnel. This system has almost wiped out any possibility of spoilage to milk. Chilling milk at grass root level and transportation of the same in road milk tankers have reduced microbial load in raw milk which in turn has reduced processing costs in terms of energy, thereby better return to farmer producers.

Geo-remote sensing based vehicle tracking system has been put in use for efficient handling of Road Milk Tankers carrying milk to Dairy Plant.

Amul Research and Development Association is a centre of excellence in the field of research and development of cattle breeding and animal health care. This Centre is recognized as a Scientific & Industrial Research Organization by the Department of Scientific & Industrial Research, Ministry of Science & Technology, Government of India. It provides quality semen for artificial insemination program; impart training to inseminators, prevention and control of diseases.